Here at Drainage Superstore, we have a wide range of channel drains to choose from, from world-leading brands including ACO, Clark Drain, Hauraton and more.

But what are channel drains and how do you install a channel drain in a driveway? Read on to find out everything you need to know about how to install channel drain products, whether you’re looking for information on how to install driveway drainage channels, how to install a channel drain in front of a garage, or even how to install a channel drain in concrete.

Table of contents

- What are channel drains?

- Different types of channel drain

- Channel drain weight load classes

- How to install a channel drain

What are channel drains?

Channel drains, also known as trench drains, linear channels or drainage channels, are designed to provide an efficient method of surface water management, particularly on non-porous surfaces, preventing ponding from occurring and ensuring even heavy downpours are dealt with effectively.

Channel drains are generally trough-shaped and are covered with gratings to prevent debris from blocking the channel drain.

Channel drains are used in a wide range of locations, varying from garage thresholds, patios and driveways to car parks, airports, swimming pools and more.

Different types of channel drain

There are several different materials that channel drains are manufactured from, and each material has its own benefits.

Plastic channel drains

Plastic, or polypropylene, is a popular material for channel drains because of its lightweight and durable characteristics. This makes transportation and installation easy and is perfect for gardens, driveways and landscaping projects. Choose plastic channel drains from ACO, Flexseal, Hauraton and more.

Concrete channel drains

For higher strength and chemical-resistant channel drains, opt for concrete channel drain systems. ACO has its very own high-strength concrete-like material, known as Vienite, which is a lightweight yet strong material with high chemical resistance. Hauraton uses fibre-reinforced concrete to provide extra stable channel drains without requiring thick walls, reducing the overall weight of the product.

Channel drain gratings

Channel drain gratings are also available in a range of materials, from plastic gratings, to cast iron gratings, ductile iron gratings, stainless steel gratings, galvanised steel gratings and even aluminium.

Channel drain weight load classes

When choosing the best channel drain for your project, it is crucial to take note of the weight load class. There are several different weight classes, and you’ll need to ensure the channel drainage you choose is suitable for the area you are looking to install it in.

Class A15 channel drainage

Channel drains that are Class A15 rated are some of the most commonly used products available. If a channel drainage product is Class A15 rated, it is suitable for pedestrian traffic only, with a maximum weight load of 1.5 tonnes. Use Class A15 channel drainage for gardens, patios and small landscaping projects.

Class B125 channel drainage

B125 channel drains are suitable for areas where the maximum weight load is up to 12.5 tonnes. B125 channel drainage is most commonly used in domestic driveways, larger patios and thresholds.

Class C250 channel drainage

Channel drains that are classed as C250 are suitable for applications with a maximum weight load of 25 tonnes. These C250 channel drains are suitable for small private car parks, roads with light traffic, and other areas, but not suitable for even infrequent lorry use.

Class D400 channel drainage

D400 channel drains are often referred to as highway channel drains, because they can withstand a maximum of 40 tonnes, making them the perfect channel drainage for main roads, highways and public car parks.

Class E600 channel drainage

Channel drains that are classed as E600 can withstand a maximum weight load of 60 tonnes. E600 channel drains are most commonly manufactured from reinforced concrete and are generally used in industrial areas such as loading bays, factories and warehouses.

Class F900 channel drainage

Class F900 channel drains are the strongest channel drainage products available. Able to withstand a maximum weight of 90 tonnes, Class F900 channel drains are most commonly used in large scale and heavy-duty industrial products, such as airports, docks and other areas that experience specific heavy machinery and transport.

How to install a channel drain

Preparation and planning

Decide where your channel drainage is going to be installed – remember that your channel drain will need to discharge, and channel drains most commonly discharge into the main drainage via a pipe union end cap, or a bottom outlet section – many channel drainage products have pop-out sections that can fit a regular drainage pipe.

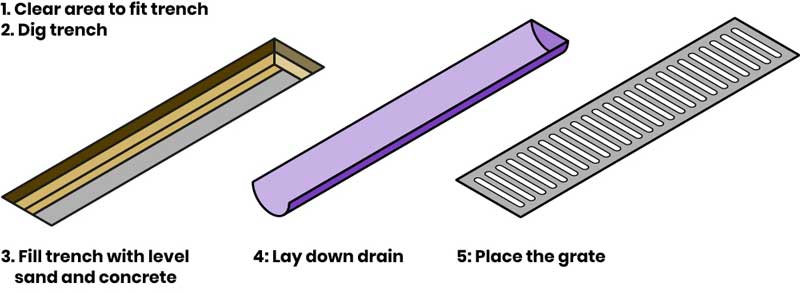

Create a trench

The first step is to dig a neat trench out of the ground, deep enough to ensure the channel drain fits neatly and reaches the surface, 2mm below the surrounding flooring, but with an extra 100mm below to allow for the application of concrete.

Drainage channel assembly

Ensure you have the correct lengths of your chosen channel drainage ready for installation, along with any required components such as a silt trap, and make sure the pre-formed outlet has been cut out. Then ensure all required end caps have been fitted before assembling the drainage channels.

Add a layer of concrete

Add a layer of concrete 100mm thick into the bottom of the trench – this can be replaced by a compacted fill if the channel drain is used in an area of pedestrian traffic only.

Insert drainage channel

Lower the channel drainage system into the prepared trench, ensuring the outlet connects and seals to the drain pipe. Use a mallet to gently press the channel drainage into the trench, before adding backfill or concrete around the channel run.

Find out how to install corner channel drains with our handy guide!

The above method can be used as guidance when looking for information on how to fit drainage channel products in a variety of situations, but we’d always recommend following the manufacturer’s instructions for more detailed information, and to ensure any warranties remain valid.

Take a look at our guide on how to install an ACO drain.

If you have any questions, queries or are looking for product recommendations regarding channel drains, don’t hesitate to get in touch – call the team on 01752 692 221 or use the live chat in the bottom right-hand corner and we will be more than happy to help.