If you’re looking for an easy way to update your driveway, why not consider block paving?

Block paving a driveway is a relatively easy way of updating your home. When done properly, it creates an attractive surface that’s hard-wearing, and long-lasting.

So, how do you block pave a driveway? We’ve outlined the steps for block paving a driveway, including some helpful tips and tricks.

Table of contents

- Benefits of block paving a driveway

- How to block pave a driveway

- Make sure to consider surface water drainage

The benefits of block paving a driveway

Attractive design

Blocked paved driveways have grown in popularity in recent years. With good reason too!

Their design enables you to have complete customisation of your driveway. Creating a sleek and incredibly attractive finish to the exterior of your home.

Their visual appeal is not the only benefit. They’re also a surface that is usable and clean.

Versatility

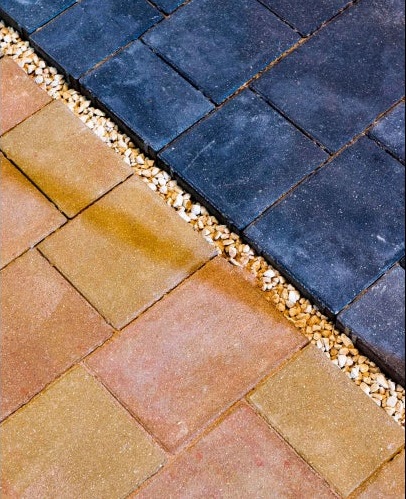

Block paving is one of the most aesthetically pleasing options available when building a driveway. They’re also incredibly versatile.

You can create all sorts of designs with blocked paving. Choose to create one with many different coloured blocks. Perhaps install lots of different block paving patterns to create a unique and attractive driveway.

Durability

As well as their versatility, block paved driveways are incredibly durable and long-lasting.

The block paving is hard-wearing. Simply replace or re-lay any individual blocks if they become damaged over time. This saves a considerable amount on maintenance and repairs.

Low maintenance

Block paving is one of the most low-maintenance forms of driveway available. This is thanks to their hard-wearing and durable characteristics.

Cleaning block paving is super simple. All they need is an occasional wash with soap and water. This keeps them functional and visually appealing.

However, it is important to note that block paving is one of the more costly options available when building a driveway. You must create a level subfloor and install each block individually. A relatively time-consuming process, but worth the hard work.

How to block pave a driveway

Block paving consists of four different elements:

- a subbase;

- an edge restraint;

- sand and;

- the blocks for paving.

How deep should subbase be for block paving?

For the heaviest domestic use, this will need a 200mm thick subbase.

For lighter traffic, the subbase can be thinner.

For areas where no traffic passes over the top, this may not need a subbase may not. As long as the ground is firm and the soil is well compacted.

A subbase is generally made up of crushed stone, quarried materials or similar materials. One that is readily available and accessible nearby.

Step one: Remove the stop soil and install the subbase

Firstly remove the topsoil and any other organic materials to the required depth. Remember that the depth needs to include a subbase, around 40mm of sand, and then the blocks on top.

Then compact the ground, and install the subbase if required. It is important to try to keep the subbase with cross falls of at least 1 in 40, and longitudinal falls of 1 in 100.

Step two: Install edge restraints

Next, install edge restraints around the edges of the area that is being block paved. Edge restraints are typically strips of plastic, steel, aluminium or PVC that are L shaped. They help keep the shape of the edge of the ground, preventing them from falling into the cut-out section of the ground.

Alternatively, use a concrete curb, or existing walls to create edging around the perimeter of the area you’re paving. If necessary, use mortar against the outside of the edging restraints to keep them secure.

Installing the block paving up to a wall? It is important to ensure the block paving sits at least 150mm below the damp-proof course. You must also make sure the driveway drains away from the wall and the building.

Step three: Lay sand across the subbase

The next step is to lay sand across the subbase. The sand should be relatively moist, enough to shape it with your hands, but not too damp that it is wet.

Ensure to lay the sand across the subbase approximately 60-65mm thick and screed it to ensure it is level. If you do not have any screed rails, just use two pieces of straight-edged timber. Place the screed rails or timber into the sand, ensuring the tops are level with the top of the sand layer.

Then take a piece of board, or another timber batten, and push it along the tops of the screed rails to create an even and level surface.

Step four: Lay the paving blocks

Now lay the blocks of your choice on top of the layer of block paving sand in the pattern of your choice.

Start laying the paving blocks from a corner or from a straight edge. Place them directly straight down, ensuring to lay them tightly next to each other. The blocks should be around 15-20mm above your desired height.

At the edges, blocks will be cut to size. To find out where you need it cut, lay it on top of where you will place it and mark that point. Then use a block splitter to cut as needed. Alternatively, use a hammer and bolster if you have experience cutting blocks.

A top tip is to use blocks from several packs at once. This will minimise the effect of any colour variation across the driveway.

Step five: Sweep and compact

After you’ve completed laying the driveway blocks, sweep some kiln-dried sand over the paving blocks. Make sure it goes into all the joints between the blocks.

Once you have swept the sand across the whole driveway, and filled all the gaps and joints, the driveway needs compacting. This is typically done using a vibrating plate. Try to use a rubber-faced compacting plate to minimise any scuffs or marks. You can often hire these plate vibrators for use from many different businesses.

When you’ve compacted the driveway, sweep more kiln-dried sand across the driveway again. Repeat the compacting process with the vibrating plate. Continue repeating until the blocks are fully compacted and filled all the joints with sand.

The driveway is now complete and ready to use. Congratulations! You now know how to lay block paving.

Block paving not your style? Try a different style by finding out how to build a gravel driveway. Learn about the benefits and use our step-by-step guidance to make sure you have the design befitting your needs.

Make sure to consider surface water drainage

Do not forget about surface water drainage when planning a driveway. You must put measures in place to allow surface water to drain away easily.

A popular choice of drainage near driveways is channel drainage. Particularly brick slot drainage channels from ACO. These are incredibly subtle yet effective. They ensure the drainage system does not detract from the driveway’s appearance.

If you’re wondering where to buy block paving, Drainage Superstore is the place to go! We offer an extensive range of patio and paving products. We also supply paving kits to allow you to make the perfect driveway.

Choose from many block paving products, or opt for natural stone paving. If you want to make a feature within your block paved driveway, we also offer many circle patio kits to make it easier.